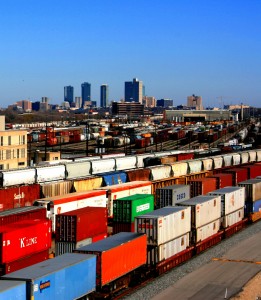

The Davidson Yard is one of the biggest west of the Mississippi. It’s got 50 miles of track and handles 500,000 cars per year, about 1,800 a day. Those cars carry sand, chemicals, plastic, food and beverage, petroleum products, paper, steel, lumber, scrap, finished automobiles, auto parts, cement, and a host of general merchandise. At least 100,000 of those cars are either delivering goods to North Texas industries or picking up finished goods made in North Texas to distribute them all over the United States. In all, tens of thousands of jobs here rely on Davidson.

A train with 123 cars and an overall length of a mile-and-a-half might come in with 10 different products. Woodson and the other men working the yard get their orders from a series of computer screens and printouts from Omaha, indicating where each car is destined. That train then gets broken down, and each car gets put on a track to be rebuilt with cars from other incoming trains. “So we’re both breaking down and rebuilding 20, 21 trains a day over the course of 24 hours. It’s pretty much nonstop.”

The whole operation is run from a six-story yard office near the west end of Davidson. The top floor has wraparound windows, several computer screens, and a couple of printers. The whole yard can be seen from there, and it looks like a beehive as cars are pushed and pulled together and apart, then sent to different tracks as if they have a mind of their own. Out on the top-floor balcony, the noise of steel wheels grinding on steel track is deafening, but the view is spectacular. Several miles in the distance, Fort Worth’s skyline stands tall against the horizon.

“Computers run the cars to where they’ve got to be,” he said, “but the whole process of planning how to build that train and making sure the connections are good for getting freight in and out [is] what we do up here in this room. That’s our purpose.

“This type of yard is called a hump yard. It’s got a hill, a hump at the far west end,” he said, pointing into the distance. “Inbound train pulls in, we pull it back and hump it — pull it back over the hill — and break it down. Then we push it out over the hill, and gravity sends it onto the right track, where it will be connected to the outbound train being built.”

He stared down into the yard. “The yard and the cars look small from up here,” he said. “But you get down in there, where it’s wall-to-wall 17-foot tall metal behemoths, and it doesn’t look small at all. And in the summer, that yard is probably 20 degrees hotter than almost anywhere else in Fort Worth.”

Some of the trains coming and going out of Davidson are daily runs. “We classify a train every day to North Platte, Nebraska, another to San Antonio, another to Little Rock, one to West Colton, California, and one to Mexico.”

The train to Mexico is run by a Union Pacific crew right up to the middle of a bridge over the Rio Grande, where the United States ends and Mexico begins. It’s then taken over by a Mexican crew. It’s the same on the way back. “Darndest place for a crew change,” he said. “But that’s how it’s done.”

Woodson’s boss is Justin Sliva, the director of terminal operations. He rattled off numbers.

“Typical Union Pacific locomotives are 74 feet long, about 11 feet wide and weigh in at 210 tons. They’ve got a pulling capacity of roughly one ton per horsepower, and most of our engines are 4,000 horsepower. A few are 3,000. A few are up to 6,000, but the majority are 4,000. When you string together three engines at the front and two in the rear, you’re talking about 20,000 horsepower, so that train can pull that many tons.”

On a flat grade, once they get going, the trains can hit speeds of 70 miles per hour, the legal limit on a top-grade track, but could do 79 if they were unfettered by laws. Wheels vary in size and weight but are typically 42 inches tall and weigh 2,200 pounds. The longest train built at Davidson is nearly two miles long — that’s the daily Little Rock train — though they’re more typically about a mile and a half. Cars range from 45 foot-long sand cars to 80-foot auto rack cars, the silver ones with the vents on the sides. The cars weigh in between 15-30 tons and carry up to about 200,000 pounds.

“When school kids ask me how much is 20,000 tons,” Sliva said, “I tell them that an elephant weighs about a ton, so you’ve got to imagine 20,000 elephants in that train to get a real idea of the weight.”

Sliva is wrong about the elephant — a full-grown African male can range from 4 and a half to 6 and a half tons — but that’s still a lot of elephants to put on that train.

Union Pacific, owner of Davidson, is the largest train outfit in the United States, he said proudly. “We run a network of 23 states and have 32,000 miles of track, all but 12 of those west of the Mississippi.”

“Why none east of the Mississippi?”

“Different companies, different rules. Our trains go all over, but our crews only take them as far as Memphis, and then crews from other companies that work east of the Mississippi take over. Just like Mexico, really.”

Sliva, has the shoulders of someone who works out regularly. His office, on the second floor of the yard office, is neat and built for efficiency. There are few decorations on the walls. Like Woodson, he loves working the trains.

He’s relaxed in conversation until the question of people jumping freights comes up. “That rarely happens,” he said.

“I’m going to interject here,” said Jeff DeGraff, a company spokesman who was also in the room. “Union Pacific takes a very strong stance against jumping trains. It sounds romantic, but in reality it’s very dangerous, and we’ll not only find you. We will prosecute. This is a very serious matter.”

“I’d say it happens less than weekly, maybe monthly,” said Sliva, diffusing the sudden tension. “Maybe less than that. It’s a non-issue.”

Later, out in the yard, the giant cars moved on the tracks in an odd sort of dance. Two oil container cars came over the hump and screeched to a halt mid-hill. On another track, three boxcars slid slowly toward a partially built train. One of them was graphitized with two stick figures’ legs from the knees down, their huge black shoes making it look as if they were walking on the side of the car. Elsewhere, an empty auto car was fixed to a long string of mixed cars. Most of the 43 tracks contained partially built or broken trains, some of them looking long enough to be nearly ready to go. In the distance was Fort Worth’s skyline. Here in The Bowl was Fort Worth’s heart.

Nice job, Peter, and you too Madeleina on the photo.